Measurement and Verification (M&V) is a formal, systematic process for determining the functional and energy saving performance of a building's energy-using systems.

Our engineers are experts in developing and implementing M&V plans in support of performance contracting, utility-sponsored energy efficiency and demand-side management programs, and LEED® projects. The M&V procedures we use include site inspections, interviews with facility personnel and operations contractors, detailed energy modeling, and short to long-term monitoring of selected system components and sub-systems. The industry accepted International Performance Measurement and Verification Protocol (IPMVP) is used as a framework for these services, and a customized M&V plan is developed according to the most appropriate IPVMP option.

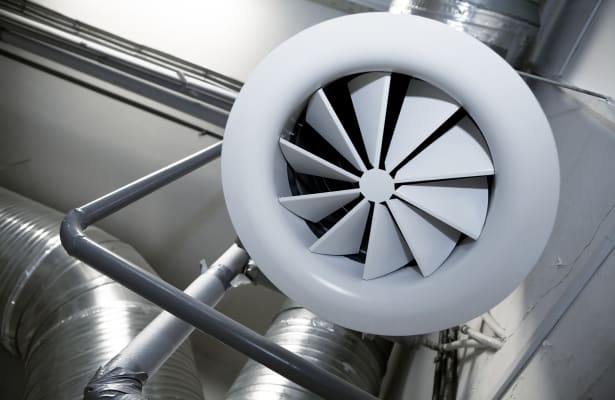

Measurement can, in some buildings, be accomplished through trending using the existing building automation system (BAS). For buildings where the BAS is inadequate for measurement purposes, we have developed an innovative suite of tools to efficiently and effectively perform on-site building measurements. Our engineers are also system diagnostics specialists. These skills integrate effectively into the M&V process, allowing us to quickly identify the points that need to be monitored, and efficiently perform the diagnostic testing to establish a system's operational and energy performance baseline from which to verify savings.

The goal of verification is to verify the savings calculations used in the original energy conservation analysis. The variables and assumptions used in the savings calculations are verified through measurement, performance data trending, system diagnostics, and utility bill analysis. By comparing the estimated savings from the energy model to the data collected through measurement, the verified or true energy savings realized by the project can be defined.

LEED® is a registered trademark owned by the U.S. Green Building Council®.